Dexon Technology just wrapped up another inspection for one of Thailand’s leading oil producers.

This time, our inspection teams were looking after the backbone of every refinery: heat exchangers.

Our goal was to:

Maximize uptime

Minimize risk

Extend lifespan

All while upholding safety standards.

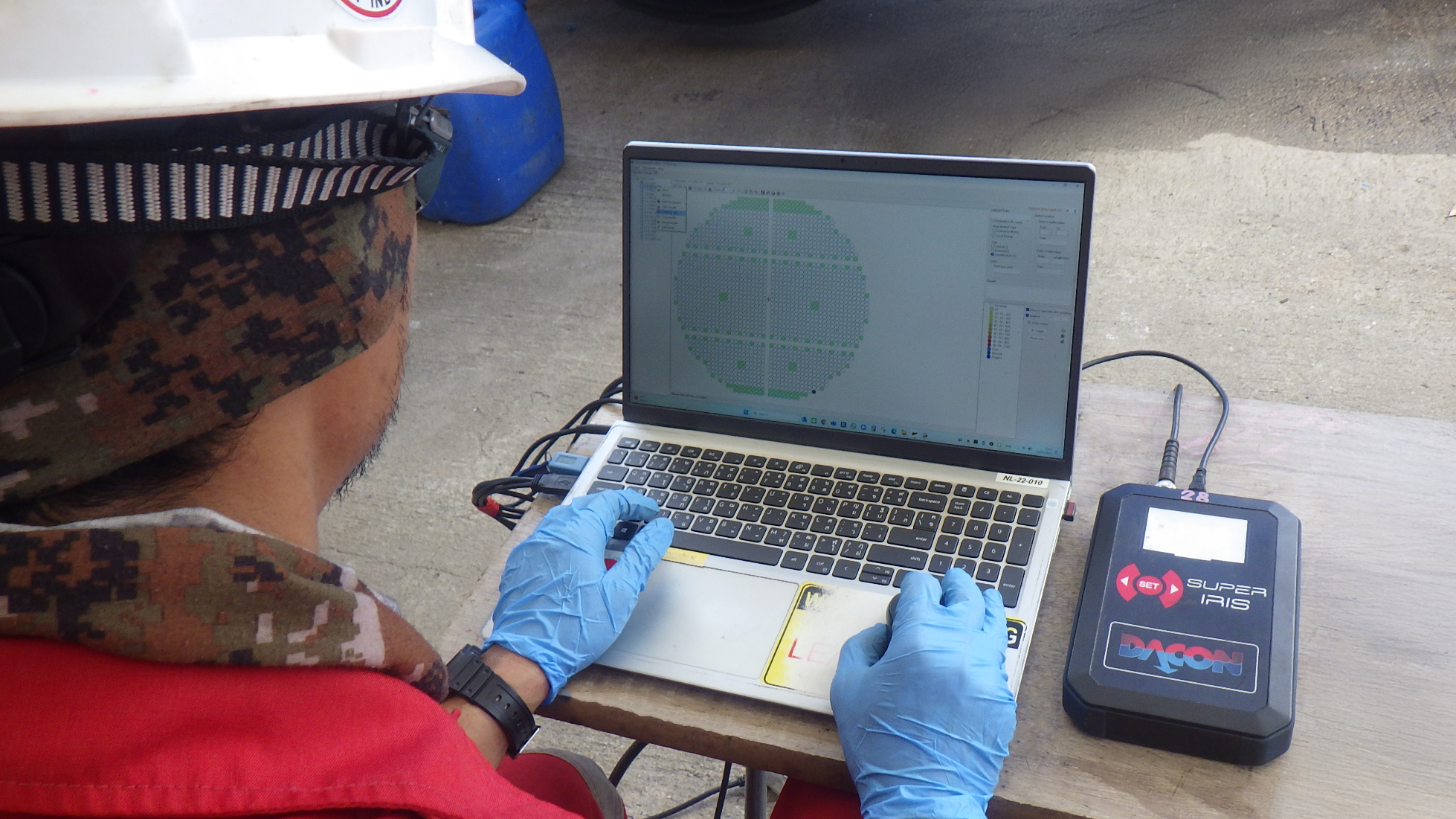

Armed with high-end tools and engineers, our crew deployed an arsenal of advanced NDT techniques:

Remote Field Testing (RFT): Internal pipe inspection using electromagnetic fields without requiring tool disassembly

Internal Rotating Inspection System (IRIS): Ultrasonic rotation to assess wall thickness and pipe integrity

Eddy Current Testing (ECT): Detects cracks and metal flaws with high precision using electrical currents

Remote Visual Inspection (RVI): High-resolution camera inspection for hard-to-reach areas

The biggest challenge for this project: logistics.

Dexon had to provide dozens of highly-trained inspectors and equip them with the latest technology—while also providing inspection services for other infrastructure on the premises.

The result: spot-on diagnostics that gave the operator confidence that they knew exactly what was going on in their heat exchangers.

If you’re an operator in need of a large, highly-trained, and well-equipped NDT team, contact us directly to speak with an expert.

Dexon Technology

Dexon Technology